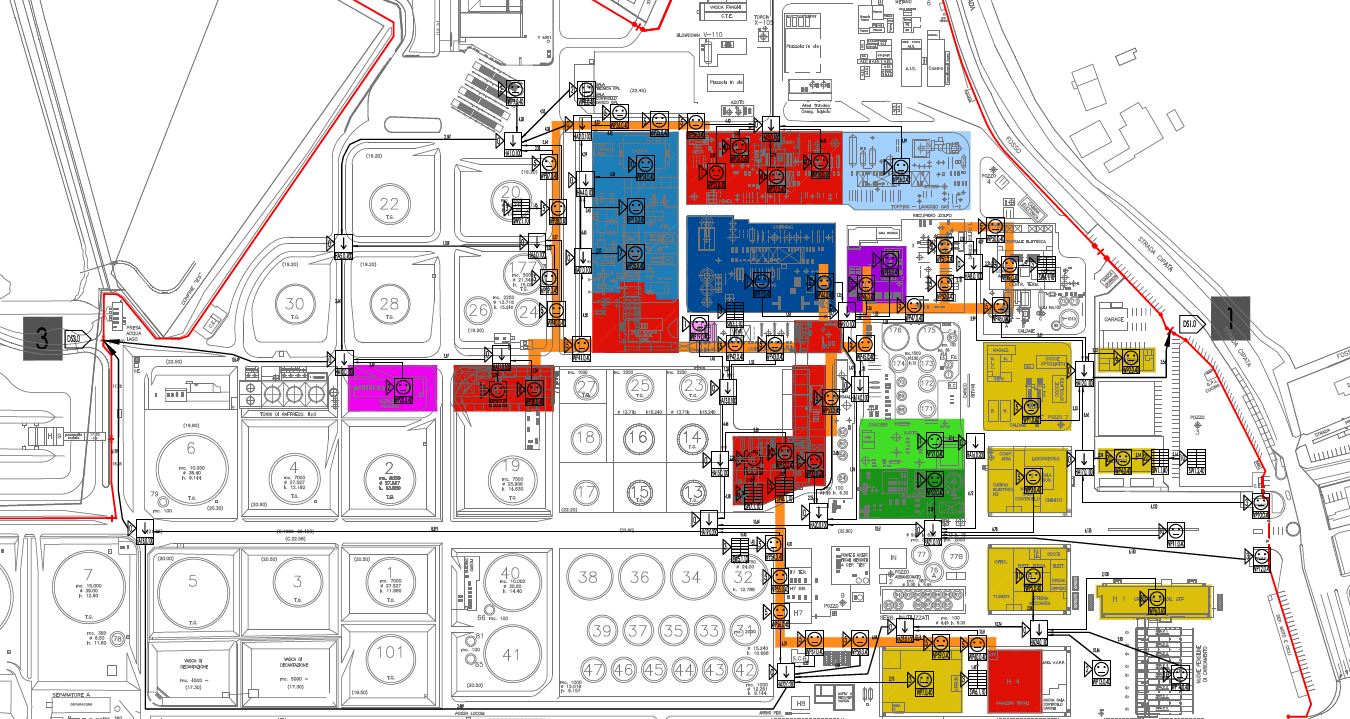

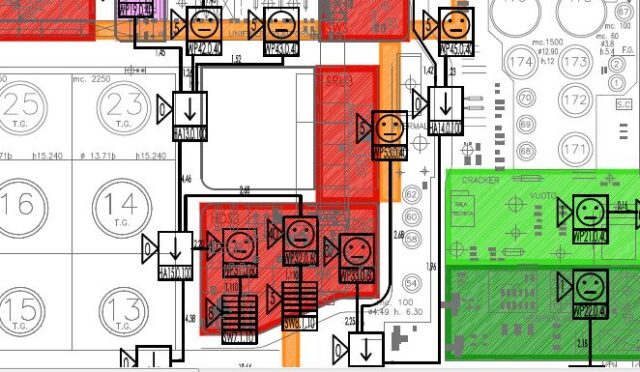

The objective of the study is to verify the suitability of the “escape system” of a refinery in consideration of possible crowding situations connected to site works planned for the construction of a new one, by means of simulation supported by a suitable calculation code applied to a suitably identified representative case study of the industrial reality under examination.

The assessment is carried out with particular reference to situations characterised by a significant presence of external personnel (e.g. major maintenance, new plant construction, etc.). In this sense, the concomitance of construction activities with the situation of a general refinery shutdown is also analysed: in this case, the operators present for new plant construction activities are added to the operators required for the shutdown, which are almost uniformly distributed in the same areas.

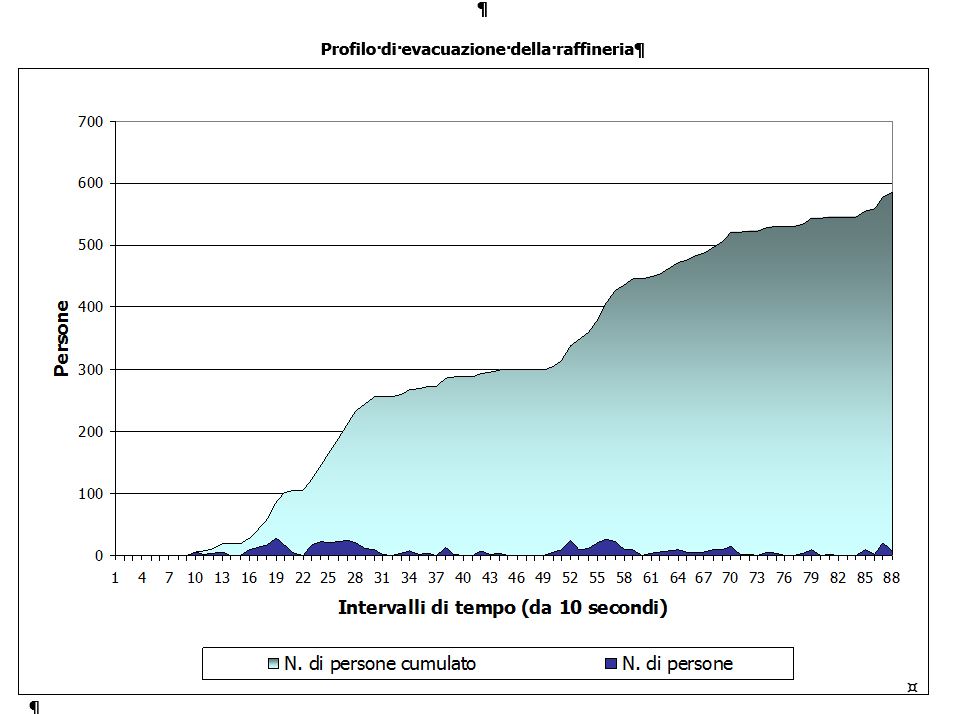

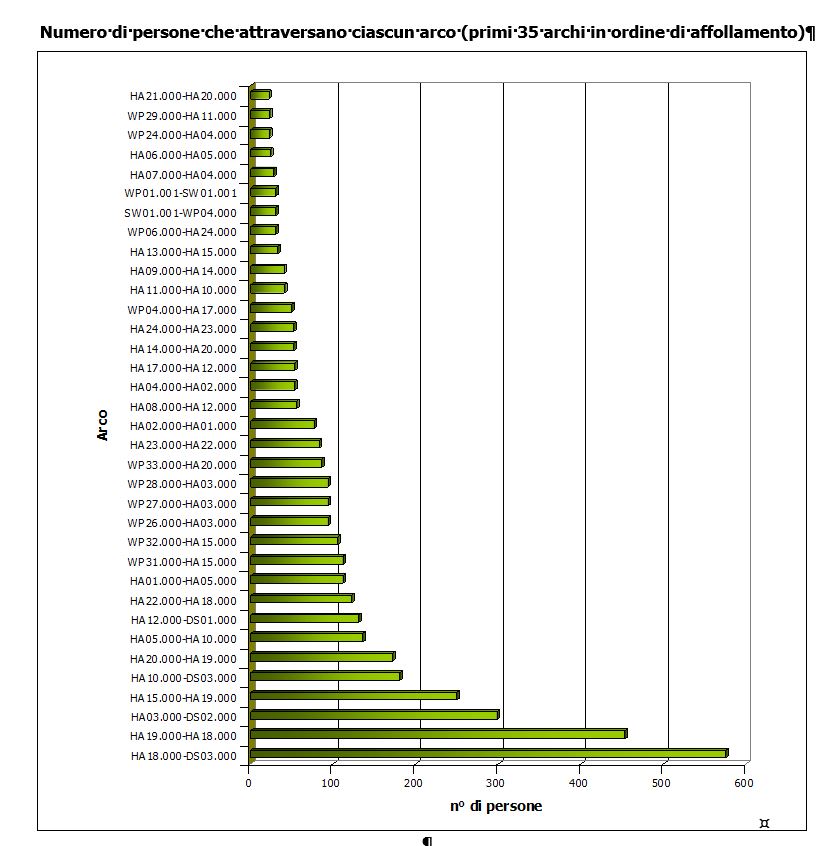

The simulation is carried out using the “EVACNET4” calculation code, a Microsoft© Windows© version of the original “EVACNET+” calculation code. The verification is carried out by simulating the performance of the entire system (escape routes, main escape manifolds, alternatives, etc.) in the configuration identified in the two case studies under examination.

The case studies have been prepared in order to identify representative situations for the site under examination and therefore two specific situations have been identified:

- base case (representing the operational situation of the refinery operation during the construction works of the new plants), named CASE 1;

- case of “general shutdown and major maintenance” (representing the situation of general refinery shutdown concomitant with plant construction works) called CASE 2.