The Main Contractor expressed interest in carrying out a series of Process Safety activities, in order to identify, with a systematic and structured approach:

- the credible hazards associated with the installations, the root causes of undesirable situations, the associated consequences, the safeguards foreseen in the project (using HazId methodology, subject of different activity);

- the effects of fire and explosion scenarios on the installations, machinery and structures of the installation, in order to provide preliminary indications on the possible active and passive fire protection systems to be foreseen within the project itself (by using the F.E.R.A. methodology, subject of different activity);

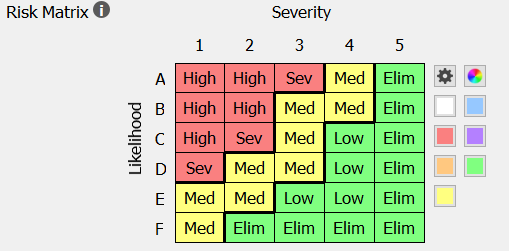

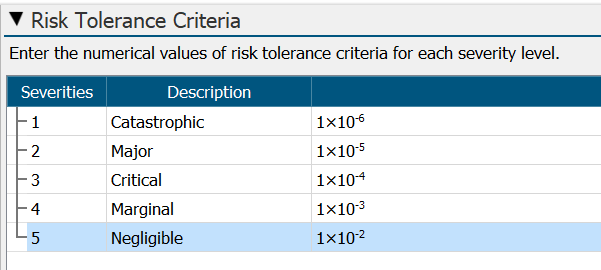

- verification, on the basis of a specific proprietary Risk Acceptance Matrix, of the acceptability of the risk level reached by the scenarios identified in the Hazard Identification (HazId) activity, and considered relevant on the basis of ranking criteria, and, for scenarios associated with risk levels not immediately acceptable, quantification of the functional requirements to be requested of specific electric, electronic or electronic programmable barriers (E/E/PE), in order to reach acceptable levels (using the LOPA methodology, subject of this activity).

The peculiarity of the activity is due to the completeness of the analytical process which, starting from the primary identification of the hazards (Hazard Identification), has allowed to reach the final step of assessing the acceptability of the risks identified and identifying the functional requirements that the electric, electronic or programmable electronic barriers (E/E/PE) must meet in order to guarantee the reduction of the risk levels to an acceptable level.

LOPA activity builds-up on the results of complementary other ones (Hazid, FERA, Fire Protection and Detection Philosophy) allowing for their inclusion in terms of conditional modifiers, enabling factors and planned or proposed safeguards.

LOPA activity made it possible to highlight the scenarios deemed relevant, making it explicit their frequency, conditional and enabling factors, associated consequences, present safeguards and independent protection levels (IPL) and, ultimately, any risk gaps to reach the level deemed acceptable.

Primatech’s PHA-Works RA® software package (HaziD integrated with Functional Integrity Level assignment LOPA activities) was used to develop the LOPA activities.