As part of the process of continuous improvement of its processes, aimed in particular at constantly reducing the environmental impact of its installations and activities, the Company has expressed its intention to proceed with the complete revamping of an important section of its plant: conversion of the electrolysis section with adaptation of the technology to the sector’s BAT-REF (“Best Available Techniques (BAT) Reference Document for the Production of Chlor-alkali”).

The activity consisted of dual-purpose assistance:

- identification of fire prevention procedures (pursuant to Presidential Decree 151/2011, Ministerial Decree 07/08/2012 and Annex L to Legislative Decree 105/2015) and prevention of major accidents (pursuant to Annex D to Legislative Decree 105/2015)

- identification of the specific process risks associated with the introduction of the new electrolysis technology.

The special nature of the activity is due, on the one hand, to the multidisciplinarity required (BAT-REF, fire prevention, major accident prevention) and, on the other, to the constraints imposed by the urban context in which the plant is located.

The implementation of the activities required specific in-depth studies:

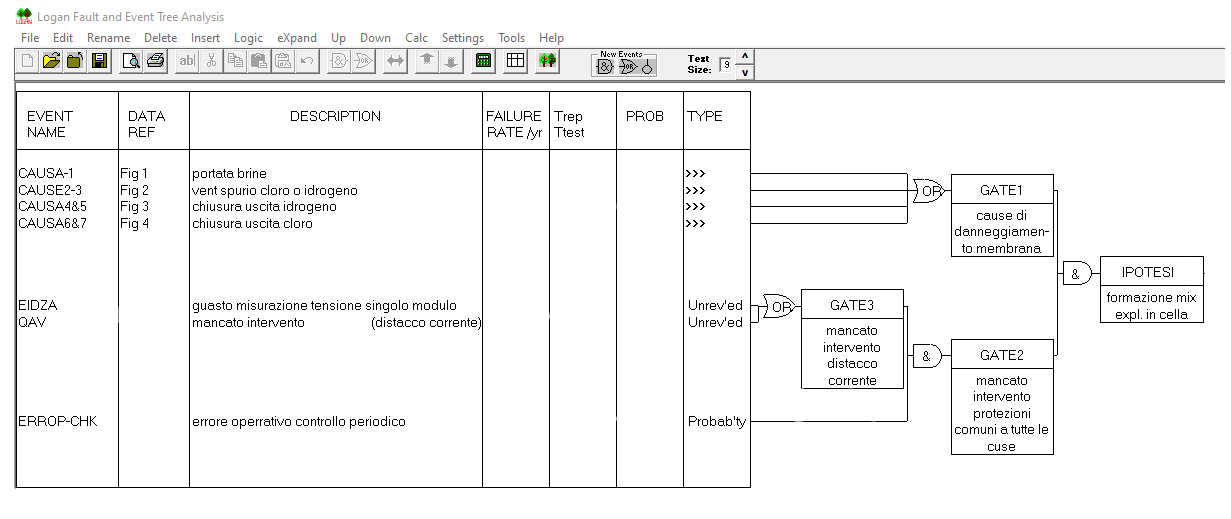

- in identification of the specific risks associated with the project, using the “Hazard and Operability” and “Fault Tree Analysis” methodologies

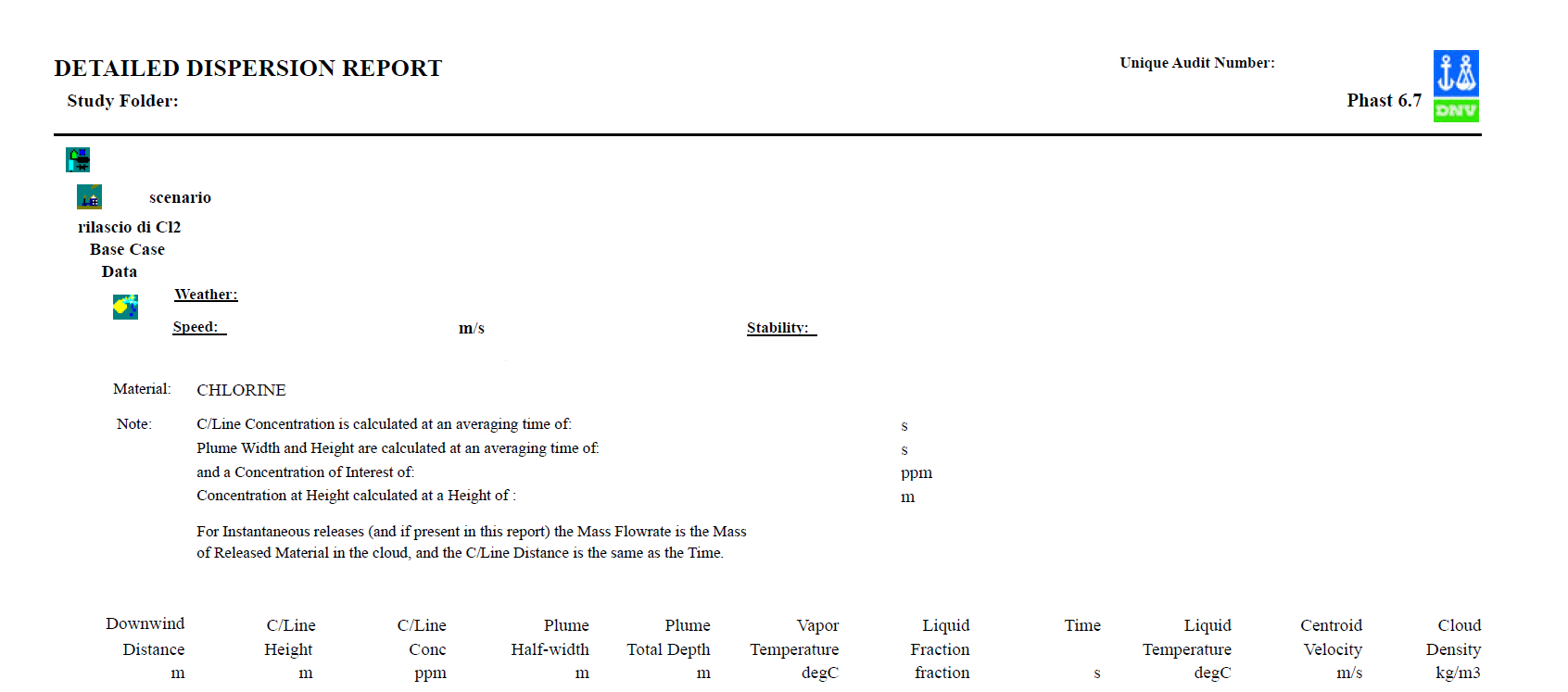

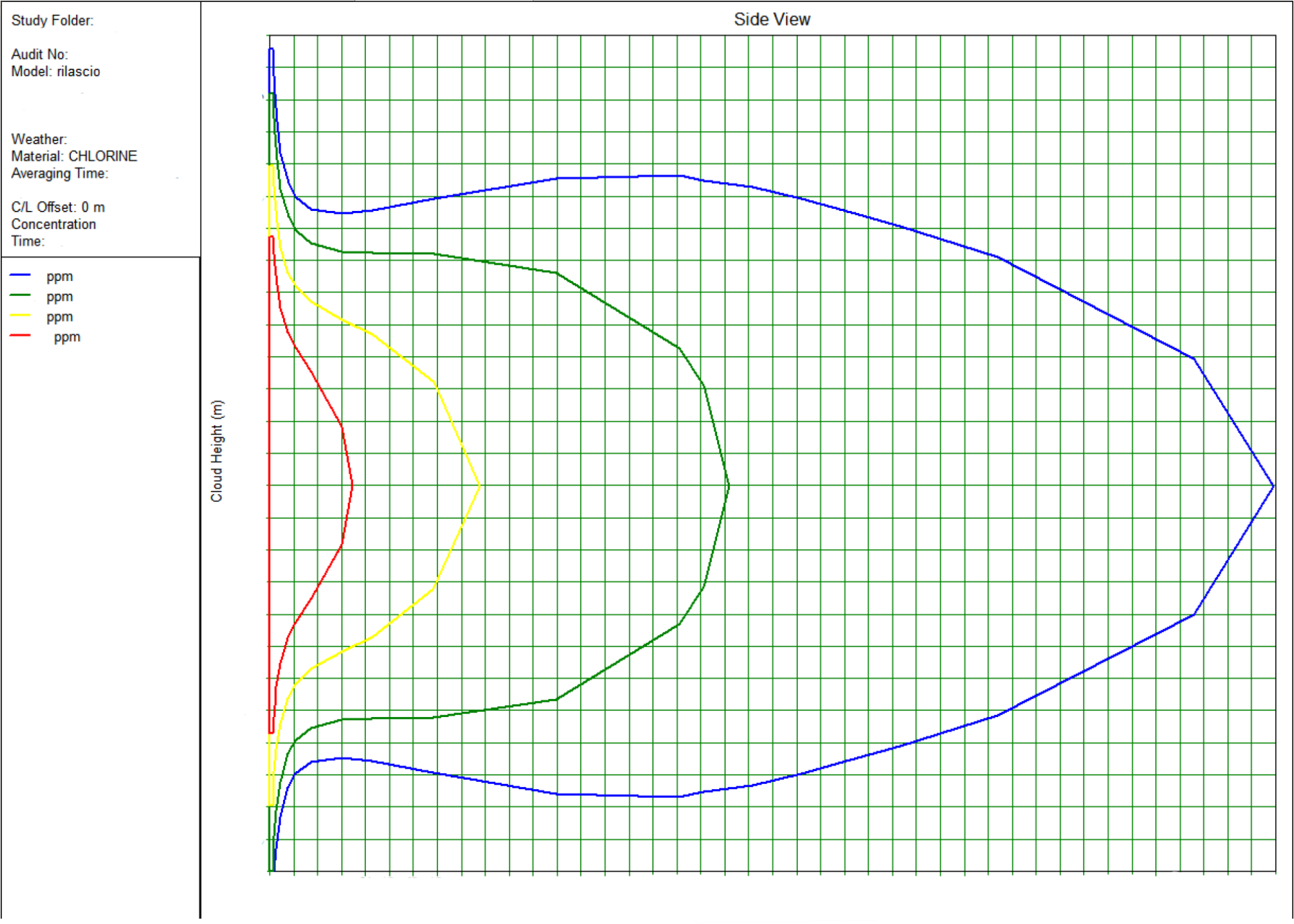

- in evaluating the consequences associated with chlorine and hydrogen releases due to random failures of primary containment systems.

PHAWorks® software from Primatech Inc. was used for the development of Hazard and Operability.

The Logan Fault Tree® software from RM Consulting was used for the development of the Fault Tree Analysis.

For the development of the consequences of the releases, the PHAST® simulator of the DNV-GL Company was used.

In the context of permitting procedures, support was also provided for interlocutions with Public Authorities.