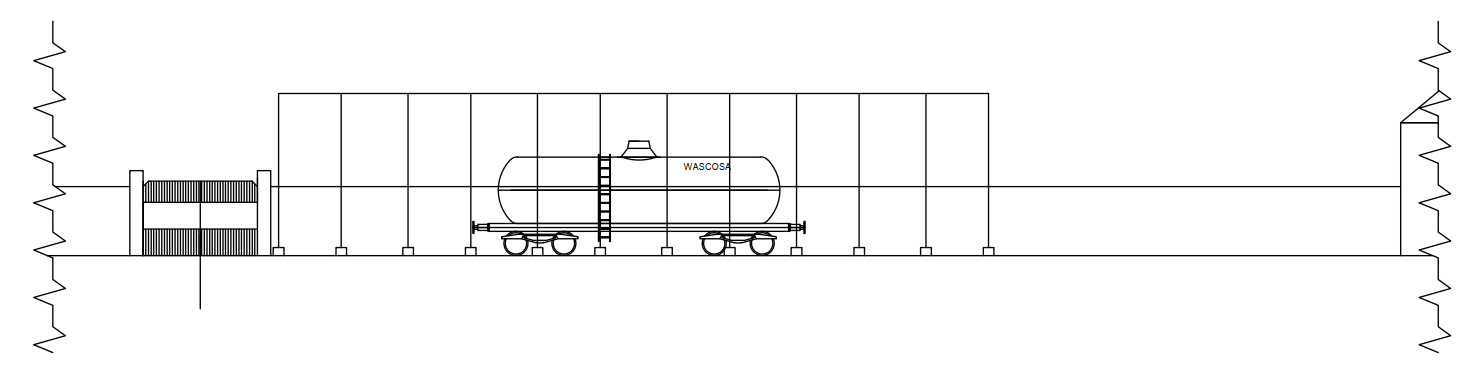

In order to evaluate the feasibility of creating a location where to “put on the trolley” (full rail tankers) / “remove from the ” (empty rail tankers), where the rail tankers are taken over by a trailer used for the transport of railway wagons, an analysis was developed of a possible overturning of the Rail Tanker in the lade/dump phases.

In order to take into consideration a possible accidental hypothesis, even if characterized by frequencies of occurrence of less than 10-6 occasions/year, the overturning of the rail tanker was hypothesized with consequent fall of the same from the trolley and perforation of the mantle with the consequent release of Chlorine.

Despite the extreme improbability of the occurrence of a puncture in the shell of the rail tanker, specific mitigation measures have been identified.

The evaporated chlorine will be conveyed to a scrubber by means of an aspiration system. This gaseous stream will be sent to a scrubber plant where the chlorine knockdown will be carried out with the use of an aqueous solution of soda.

On the short sides of the Tarpaulin Shed Structure, left open to allow the rail tanker and the trolley to pass, two water curtains will be installed in order to contain the dispersion of chlorine inside the structure. The water curtains will be characterized by a specific flow rate equal to 50 l / min / linear meter.

The detection will be carried out by means of portable detectors supplied to the operators, who will proceed, in addition to the activation of the water barriers, also to block the leak by means of metal wedges, resins or bands.