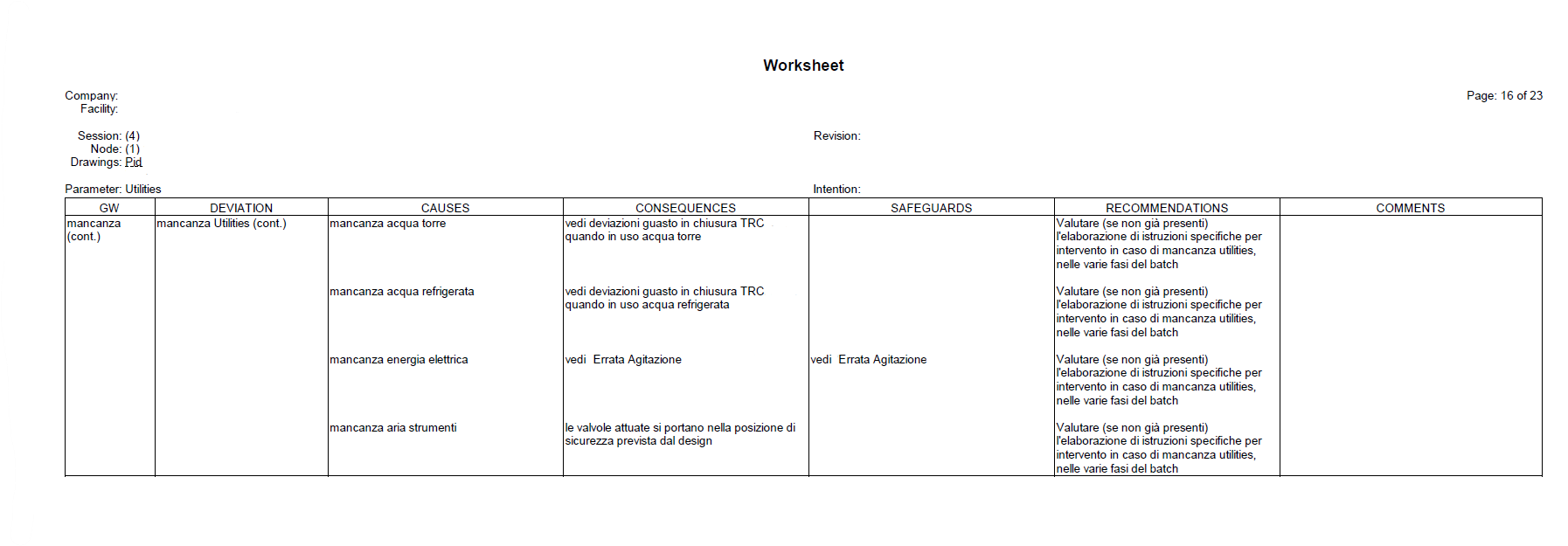

Following the introduction of a new production process for an active ingredient obtained by fermentation process, the Company expressed interest in investigating the process risks associated with the new process, to be carried out at the existing facilities of its plant, suitably adapted for the development of the process.

The activity involved two different sections of the plant:

- “up-stream” section for the synthesis itself

- “down-stream” section for finishing the molecule

The peculiarity of the activity is due to the extension of the analysis, about 20 P&Id were analyzed in 10 hazop sessions and to the way in which the sessions were carried out, as they were held in VDC synchronous mode between the Customer’s offices and those of Tecsa.